Techniques for Suspect/Counterfeit EEE Parts Detection by External Visual Inspection, check for ESD protection, Package and Dimension Check, Device Markings, Pin Indicator Orientation, Lead/BGA Condition and Inspection and Substrate Condition.

Techniques for Suspect/Counterfeit EEE Parts Detection by solvent resistance resurfacing, check for Blacktopped and Remarking.

Techniques for Suspect/Counterfeit EEE Parts Detection by Heated Chimical Test for Remarking and Resurfacing, Check for secondary Coating, scratch, ghost marking and Remarking

Techniques for Suspect/Counterfeit EEE Parts Detection by Delid/Decapsulation Physical Analysis Test Methods, check for Die confirmation and authentication.

Techniques for Suspect/Counterfeit EEE Parts Detection by Radiological Test Methods, check for Wire Bonding verification, Structure Analysis, Die size comparison, Homogeneousness of the batch structure.

Techniques for Suspect/Counterfeit EEE Parts Detection by X-ray Fluorescence Test Methods, a lead finish examination is performed on the sample devices to Check Leaded, LeadFree or RohS status.

Techniques for Suspect/Counterfeit EEE Parts Detection by Electrical Test Methods, Pin correlation, DC Resistance, Capacitance, Inductance,

Memory / Flash / Programming.

Techniques to provide a means of determining the solderability of device package terminations that are intended to be joined to another surface.

Techniques for Suspect/Counterfeit EEE Parts Detection by scraping the surfacing of the device, check for Recoating, Blacktopped and Remarking.

After testing all devices are reconditioned compliant to Humidity and ESD protection standard.

Magen Laboratories is a complete Test Laboratory solution for Component Authentication and to protect yourself from counterfeit electronics components.

Our test and analysis capabilities were developed by an engineering staff with decades of semiconductor industry experience and in continual development to new technologies to provide best test services at effective cost.

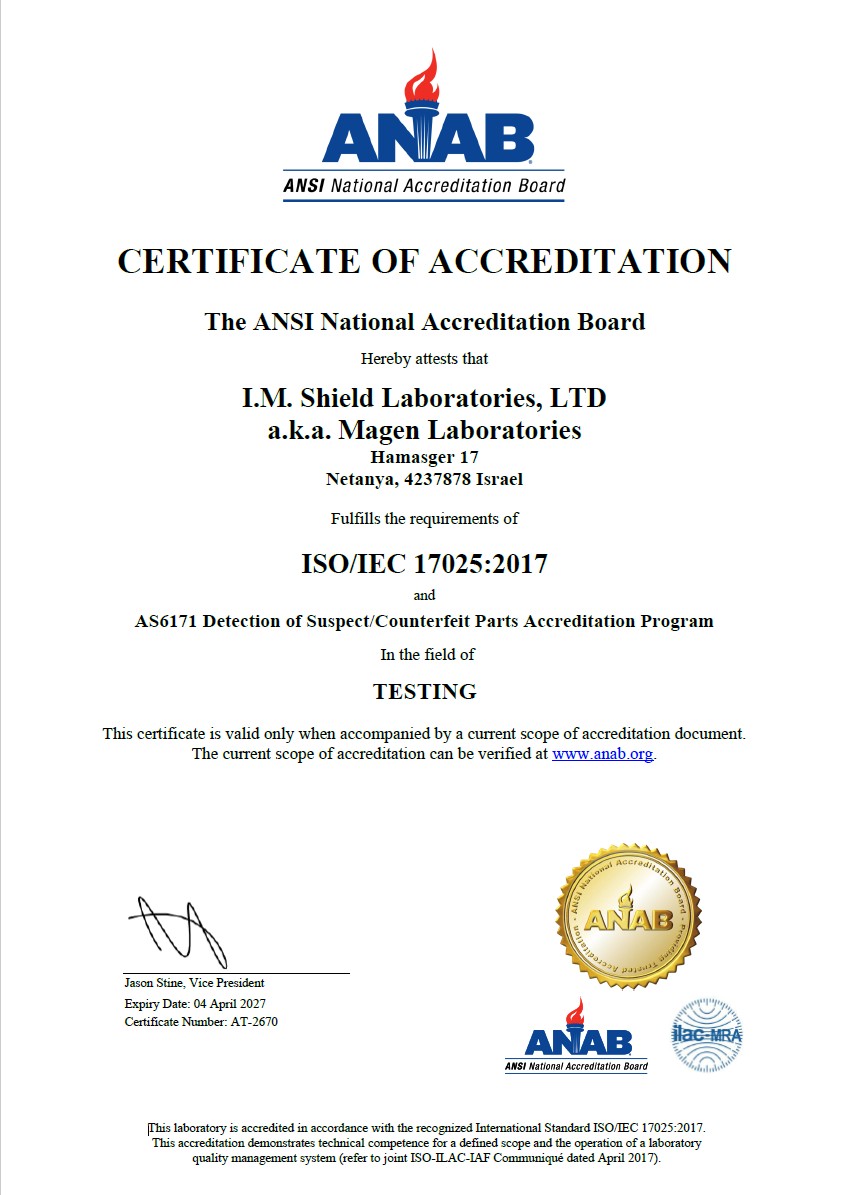

Magen Laboratories is Accredited ISO/IEC 17025:2017 testing laboratory for international standards: AS5553, AS6081, AS6171, MIL-STD-883 and IDEA-STD-1010B.

Dear All, In a spirit of perfection and always gives the best to these customers, Magen Laboratories purchased the KEYSIGHT SMU B2901A, With this device you …

All Magen Lab employees are continuous training on all new testing technologies.

>עופר אלוף מהנדס בדיקות י.מ. מגן מעבדות בע”מ רכיבים אלקטרוניים מזויפים בשרשרת האספקה קיימים ויכולים לפגוע בבטיחות ובאמינות של כול מוצר צריכה אלקטרוני ובנוסף …

+972-9-9568352

HAMASGER ST 17, Z.I. NORTH NETANYA,

4237878, PO Box: 13604, ISRAEL